WD-SJ617埋弧焊用烧结焊剂

WD-SJ617为带极电渣堆焊用焊剂,为细粉状颗粒,采用平特性直流电源堆焊,电渣过程稳定,快速脱渣,焊道成形美观,焊道间搭接处熔合良好,具有不增碳、Cr烧损少的特点。适用于宽度30~75mm的焊带进行电渣堆焊。

所属分类:

· 堆焊焊剂

咨询热线:

- 产品描述

-

- 商品名称: WD-SJ617埋弧焊用烧结焊剂

- 商品编号: 1057227722712768512

WD-SJ617为带极电渣堆焊用焊剂,为细粉状颗粒,采用平特性直流电源堆焊,电渣过程稳定,快速脱渣,焊道成形美观,焊道间搭接处熔合良好,具有不增碳、Cr烧损少的特点。适用于宽度30~75mm的焊带进行电渣堆焊。

符合标准:

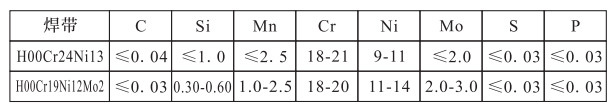

GB/T17854 F309L-H00Cr24Ni13 F316L-H00Cr19Ni12Mo2

说明:

WD-SJ617为带极电渣堆焊用焊剂,为细粉状颗粒,采用平特性直流电源堆焊,电渣过程稳定,快速脱渣,焊道成形美观,焊道间搭接处熔合良好,具有不增碳、Cr烧损少的特点。适用于宽度30~75mm的焊带进行电渣堆焊。

用途:

可用于核容器、加氢反应器及压力容器等耐腐蚀不锈钢的堆焊。

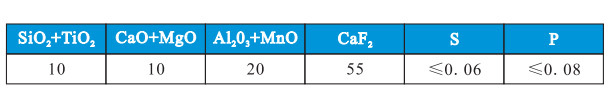

焊剂化学成分参考值(%):

堆焊金属化学成分参考值(%):

注意事项:

1、焊剂在使用前须经300-350°C烘焙2小时。

2、焊前应清除焊件上的铁锈、油污、水分等杂质。

关键词:- 堆焊

- 焊剂

- 焊道

上一页

下一页