WD-SJ612埋弧焊用烧结焊剂

WD-SJ612焊剂是- -种碱度约为1.0的硅钙型烧结焊剂。配合低碳和超低碳不锈钢焊带,用于在低碳钢和低合金钢.上不锈钢过渡层的电弧带极堆焊。

所属分类:

· 堆焊焊剂

咨询热线:

- 产品描述

-

- 商品名称: WD-SJ612埋弧焊用烧结焊剂

- 商品编号: 1057227697077182464

WD-SJ612焊剂是- -种碱度约为1.0的硅钙型烧结焊剂。配合低碳和超低碳不锈钢焊带,用于在低碳钢和低合金钢.上不锈钢过渡层的电弧带极堆焊。

符合标准:

GB/T17854 F309-H0Cr24Ni13 F308L-H00Cr24Ni13

说明:

WD-SJ612焊剂是- -种碱度约为1.0的硅钙型烧结焊剂。配合低碳和超低碳不锈钢焊带,用于在低碳钢和低合金钢.上不锈钢过渡层的电弧带极堆焊。为了防止铬的过量烧损,焊剂中含有一定量铬以补充烧损。

用途:

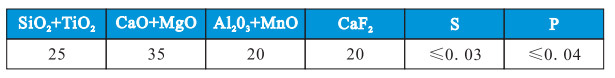

用于化工容器、加氢反应器内壁及管板的不锈钢过渡层的电弧带极堆焊。焊剂化学成分参考值(%):

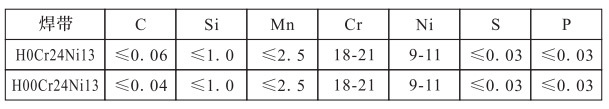

堆焊金属化学成分参考值(%):

注意事项:

1、焊剂在使用前须经300-350°C烘焙2小时。

2、焊前应清除焊件上的铁锈、油污、水分等杂质。

关键词:- 焊剂

- 堆焊

- 不锈钢

- 电弧

上一页