WD-SJ8016埋弧焊用烧结焊剂

WD-SJ8016是一种碱度约为2.6的铝碱型烧结焊剂,外观为10-60目(2.0-0.28mm)的淡黄色圆形颗粒,松装密度小,适于较小的焊接电流,电流采用直流电源,焊丝接正极。

所属分类:

· 堆焊焊剂

咨询热线:

- 产品描述

-

- 商品名称: WD-SJ8016埋弧焊用烧结焊剂

- 商品编号: 1057227826437906432

WD-SJ8016是一种碱度约为2.6的铝碱型烧结焊剂,外观为10-60目(2.0-0.28mm)的淡黄色圆形颗粒,松装密度小,适于较小的焊接电流,电流采用直流电源,焊丝接正极。

符合标准:

GB/T17854 F410-H1Cr13/F308-H0Cr21Ni10

说明:

WD-SJ8016是一种碱度约为2.6的铝碱型烧结焊剂,外观为10-60目(2.0-0.28mm)的淡黄色圆形颗粒,松装密度小,适于较小的焊接电流,电流采用直流电源,焊丝接正极。焊接工艺性能良好,易脱渣,成形美观,堆焊金属具有优良的抗晶间腐蚀性能和抗脆化性能。焊剂的熔敷金属为13Cr系和Cr21Ni10系,配合Cr13系列实芯焊丝、药芯焊丝、H0Cr21N10焊丝等,广泛用于合金钢、高合金钢和不锈钢的自动焊接和硬面堆焊,特别适于硬面辊易磨件的修复堆焊。

用途:

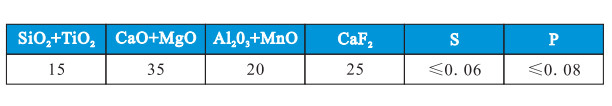

可用于堆焊各类硬面辊,如堆焊连续铸造辊、轧机辊及送进辊。焊剂化学成分参考值(%):

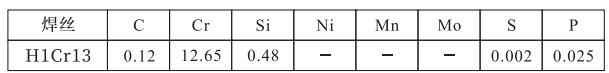

熔敷金属成分参考值(%):

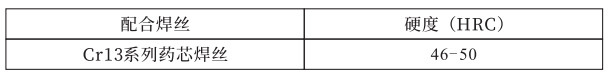

硬度参考值:

注意事项:

1、焊剂在使用前须经300-350°C烘焙2小时。

2、焊前应清除焊件上的铁锈、油污、水分等杂质。

3、焊前预热300-400°C

关键词:- 堆焊

- 焊丝

- 焊剂

- 焊接

上一页