- 产品描述

-

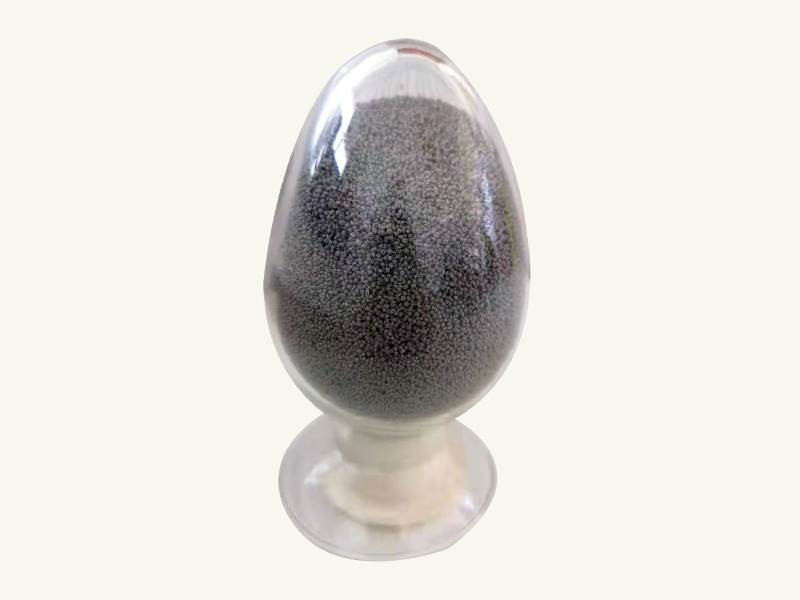

- 商品名称: WD-SJ501埋弧焊用烧结焊剂

WD-SJ501是铝钛型烧结焊剂,外观为球形颗粒,粒度10-60目。

WD-SJ501 / WD-H08A

符合:

GB/T 5293 S43A0AR-SU08A

AWS A5.17 F43AZ-EL8

ISO 14171-B-S43A0AR-SU08说明及用途:

WD-SJ501是铝钛型烧结焊剂,外观为球形颗粒,粒度10-60目。配合H08A碳钢埋弧焊丝,焊接工艺性优良;焊缝金属纯净;硫、磷含量低;综合性能良好。适用于钢结构、螺旋管、钢瓶等相应级别的碳钢埋弧自动焊接。

焊丝化学成分参考值:

WD-H08A

C

Mn

Si

S

P

GB

≤0.10

0.40-0.65

≤0.030

≤0.030

≤0.030

例值(Example)

0.07

0.60

0.018

0.010

0.013

焊剂化学成分参考值:

WD-SJ501

Al2O3+TiO2

S

P

标准(Standard)

≥40

≤0.050

≤0.060

熔敷金属化学成分参考值:

C

Mn

Si

S

P

GB

——

——

——

≤0.030

≤0.030

例值(Example)

0.065

1.05

0.56

0.015

0.026

熔敷金属力学性能:

WD-SJ501

WD-H08A

抗拉强度(TS) MPa

屈服强度(YS)

MPa延长率(A)

%冲击吸收能量KV2(J)

热处理

℃×h0℃

GB

430-600

≥330

≥20

≥27

焊态

AWS

430-560

≥330

≥22

≥27

焊态

例值(Example)

450

350

30

66,76,70

焊态

注意事项:

(1)焊接前焊剂必须经过300℃-350℃烘干两小时。

(2)焊接前必须对工件清除铁锈、油污、水分等杂质。

(3)多层(道)焊接时必须将焊渣清理。注意层间温度控制在150℃-250℃。关键词:- wd-sj501

- 焊接

- 焊剂

- 酸性

上一页