WD-308L不锈钢用带极堆焊钢带

WD-308L主要成分是低C-18Cr-8Ni,可使用于带极埋弧堆焊和电渣堆焊。WD-308L在WD-309L过度堆焊层上堆焊成型,亦可在带极电渣堆焊方法中单层堆焊成型。堆焊效率高,母材稀释率低;焊道成型美观。

所属分类:

· 碳钢焊剂

咨询热线:

- 产品描述

-

- 商品名称: WD-308L不锈钢用带极堆焊钢带

WD-308L主要成分是低C-18Cr-8Ni,可使用于带极埋弧堆焊和电渣堆焊。WD-308L在WD-309L过度堆焊层上堆焊成型,亦可在带极电渣堆焊方法中单层堆焊成型。堆焊效率高,母材稀释率低;焊道成型美观。

符合标准:

JB/T4747 HD308L AWS A5.9 EQ308L EN12072 19 9L ISO 14343 B-BS308L

说明:

WD-308L主要成分是低C-18Cr-8Ni,可使用于带极埋弧堆焊和电渣堆焊。WD-308L在WD-309L过度堆焊层上堆焊成型,亦可在带极电渣堆焊方法中单层堆焊成型。堆焊效率高,母材稀释率低;焊道成型美观。搭接熔合平滑,堆焊金属中杂质元素含量低。

用途:

广泛应用于石化行业中加氢设备、核容器、尿素设备、海洋平台设备等的堆焊使用。

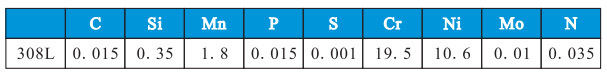

焊丝及熔敷金属化学成分参考值(%) :

注意事项:

1、焊前严格对母材打磨,去除铁锈、油污等影响焊接的因素,必须预热。

2、过渡层堆焊时,在保证焊道成型的前提下尽量降低过渡层堆焊厚度(3-3.5 mm);耐蚀层堆焊时,在保证焊道成型的前提下可以适当增加耐蚀层的厚度(3.5-4 mm)。

3、使用平特性电源效果更好。

4、堆焊位置以水平至2°左右的上坡焊为宜。

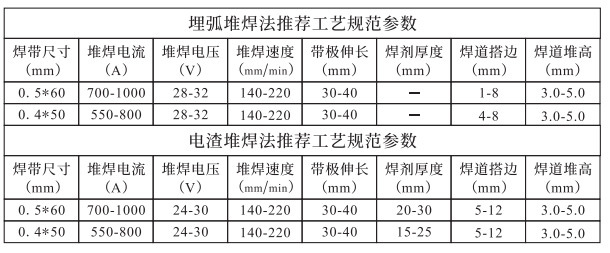

推荐焊接参数:

关键词:

关键词:- 不锈钢

- 堆焊

- 焊道

- 设备

下一页