WD-8018埋弧焊用烧结焊剂WD-8018 SAW FLUX

符合标准:GB/T17854-1999AWSA5.9M-2006ER2209 认证机构:CCS

所属分类:

· 不锈钢焊剂

咨询热线:

- 产品描述

-

- 商品名称: WD-8018埋弧焊用烧结焊剂WD-8018 SAW FLUX

符合标准:GB/T17854-1999AWSA5.9M-2006ER2209 认证机构:CCS

符合标准:

GB/T 17854-1999 AWS A5.9M-2006 ER2209

认证机构:CCS

说明:WD-8018 是氟碱型碱性烧结焊剂,碱度约为2.5(BIIW),为乳黄色球形颗粒,直流施焊时焊丝接正极,最大焊接电流可达1200A,粒度为10~50目。该焊剂与焊丝ER2209配套焊接,熔敷金属纯净,烧损元素较少,具有较高的抗拉强度和屈服强度;实验数据满足美国标准(AWS),有比较高的铁素体含量,焊后渣壳翘起,窄间隙脱渣容易,焊缝成形美观,电弧燃烧稳定,抗吸潮性好,颗粒强度高,松装密度小,焊接过程中焊剂消耗量少。

用途:可用于石油化工设备、海水与废水处理设备、输油气管线、化工用船舶焊接。

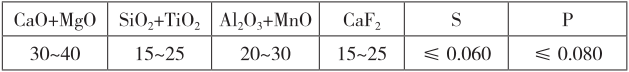

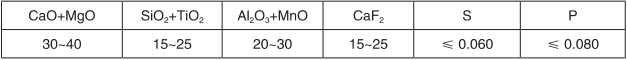

焊剂参考成分(%):

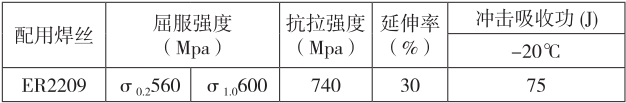

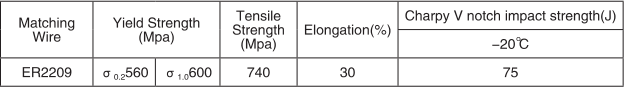

焊缝金属力学性能典型值:

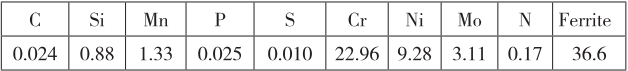

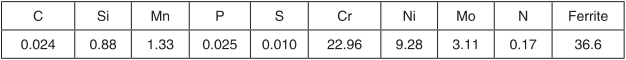

熔敷金属化学金属成分:

注意事项:

1、焊剂如果受潮,在使用前须经300~350℃烘焙2小时。

2、焊接处须清除铁锈、油污、水分等杂质。

WD-8018 Agglomerated Flux For S.A. WeldingStandards: GB/T 17854-1999 AWS A5.9M-2006 ER2209Approvals: CCSIntroductionWD-8018 is an agglomerated fluoride-basic type flux with a basicity index of BIIW 2.5. The flux is yellow spherical granular. WD-8018 can be welded with DC at up to 1200A,connect the welding wire to the positive terminal when with DC. Grain size is from 10 to 50 mesh. This flux is for matching with ER2209 welding wire, deposited metal is pure, burning loss is low, has high tensile strength and yield strength; Test result meets AWS standard, has high content of delta ferrite, slag removal is easy in the narrow gap. Bead appearance is beautiful, burn-out of the arc is stable, slag is easy to remove. The flux has low moisture pick-up and granular stability. As the bulk density is low, its consumption rate are few.ApplicationsWelding of petrochemical industry equipments, treatment equipments of seawater and waste water, oil and gas pipelines, ships for chemical engineering.Main Constituents (%) Typical mechanical property of deposited metal

Typical mechanical property of deposited metal Typical chemical composition of deposited metal (%)

Typical chemical composition of deposited metal (%) Notice:1. Flux should be redried at 300~350°C for 2 hours.2. All dust, oil and rust should be removed关键词:

Notice:1. Flux should be redried at 300~350°C for 2 hours.2. All dust, oil and rust should be removed关键词:- 焊剂

- 焊接

- 金属

- 焊缝

- 焊丝

- er2209

- 标准

- aws

- 强度

上一页

下一页