WD-SJ68埋弧焊用烧结焊剂

WD-SJ68是一种碱度约为2.4的铝碱型烧结焊剂,外观为10-60目(2.0-0.28mm)的灰黑色球形颗粒。此焊剂抗吸潮性能好;颗粒强度高;松装密度小;焊接过程中焊剂消耗量少。

所属分类:

· 高强钢焊剂

咨询热线:

- 产品描述

-

- 商品名称: WD-SJ68埋弧焊用烧结焊剂

WD-SJ68是一种碱度约为2.4的铝碱型烧结焊剂,外观为10-60目(2.0-0.28mm)的灰黑色球形颗粒。此焊剂抗吸潮性能好;颗粒强度高;松装密度小;焊接过程中焊剂消耗量少。

符合标准:

GB/T5293 S55A3AB-SU4M32 AWS A5.23M-97 F8A3-EA3 14174-S A AB 1

说明:

WD-SJ68是一种碱度约为2.4的铝碱型烧结焊剂,外观为10-60目(2.0-0.28mm)的灰黑色球形颗粒。此焊剂抗吸潮性能好;颗粒强度高;松装密度小;焊接过程中焊剂消耗量少。该焊剂在焊接过程中最大焊接电流可达1200A且电弧稳定;焊后形成短渣;窄间隙脱渣容易;在焊接小直径圆筒时不淌渣;焊缝成形美观;熔敷金属纯净,SiO2含量低;减少了硅的过渡;具有较高的低温冲击韧性。直流焊接时焊丝接正极。配合相应的焊丝,采多层焊、双面单道焊、多丝焊和窄间隙埋弧焊等,可焊接较高强度船用钢、压力容器用钢、管线钢、海洋平台及细晶粒结构钢,用于重要的焊接产品。

用途:

可用于船舶、压力容器、贮罐、钢结构、桥梁、螺旋焊管等结构的对接及角接焊缝。

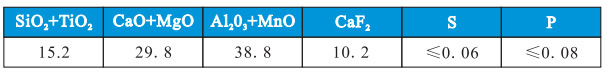

焊剂化学成分参考值(%):

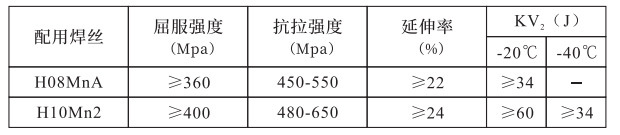

熔敷金属力学性能参考值:

注意事项:

1、焊剂在使用前须经300-350°C烘焙2小时。

2、焊前应清除焊件上的铁锈、油污、水分等杂质。

关键词:- 焊剂

- 焊接

- 焊缝

- 焊丝

上一页

下一页